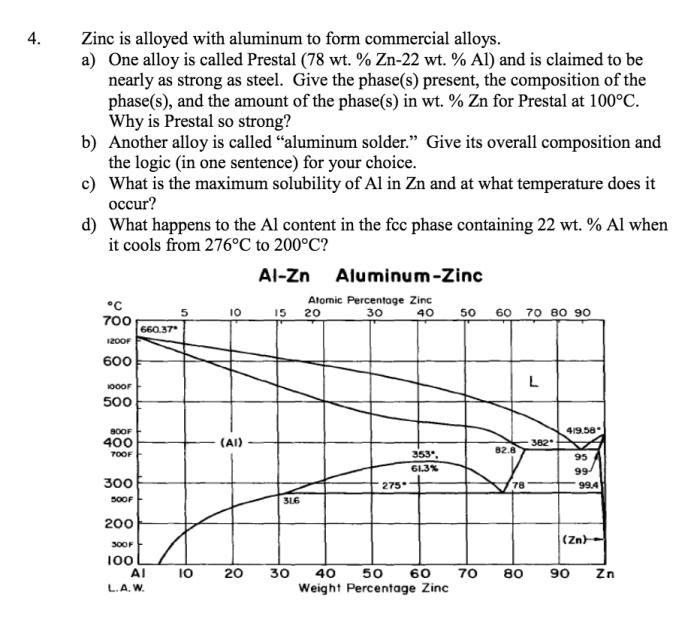

Composition of an aluminum-zinc alloy prelab – The composition of aluminum-zinc alloys is a crucial factor in determining their properties and applications. This prelab explores the composition, properties, and preparation techniques for aluminum-zinc alloys, providing a comprehensive overview for further experimentation and analysis.

Aluminum-zinc alloys exhibit a unique combination of strength, corrosion resistance, and thermal conductivity, making them suitable for various industries, including automotive, aerospace, and construction.

Composition of Aluminum-Zinc Alloy

Aluminum-zinc alloys are composed of aluminum and zinc, with the proportions of each metal varying depending on the desired properties of the alloy. The most common type of aluminum-zinc alloy is 5052, which contains approximately 2.5% zinc. Other types of aluminum-zinc alloys include 5083, 5086, and 5182, which have different zinc contents and mechanical properties.

Types of Aluminum-Zinc Alloys and Their Applications

- 5052:Used in marine applications, architectural trim, and automotive parts due to its high strength and corrosion resistance.

- 5083:Used in welded structures, pressure vessels, and automotive parts due to its good formability and weldability.

- 5086:Used in automotive parts, electrical components, and heat exchangers due to its high strength and corrosion resistance.

- 5182:Used in marine applications, architectural trim, and automotive parts due to its high strength and corrosion resistance.

Properties of Aluminum-Zinc Alloy: Composition Of An Aluminum-zinc Alloy Prelab

Mechanical Properties

- Strength:Aluminum-zinc alloys have high strength, making them suitable for structural applications.

- Hardness:Aluminum-zinc alloys are harder than pure aluminum, providing increased wear resistance.

- Ductility:Aluminum-zinc alloys have good ductility, allowing them to be easily formed and shaped.

Corrosion Resistance

Aluminum-zinc alloys have excellent corrosion resistance, making them suitable for use in harsh environments. The zinc content forms a protective layer on the surface of the alloy, preventing corrosion.

Thermal Conductivity, Composition of an aluminum-zinc alloy prelab

Aluminum-zinc alloys have high thermal conductivity, making them suitable for heat transfer applications. The zinc content increases the thermal conductivity of the alloy.

Essential FAQs

What is the typical composition range of aluminum-zinc alloys?

Aluminum-zinc alloys typically contain between 4% and 22% zinc by weight, with the remainder being aluminum.

What are the key mechanical properties of aluminum-zinc alloys?

Aluminum-zinc alloys offer high strength, hardness, and ductility, making them suitable for structural applications.

How can the corrosion resistance of aluminum-zinc alloys be improved?

Adding small amounts of magnesium to aluminum-zinc alloys significantly enhances their corrosion resistance.